Cable Paper vs. Insulation Presspaper: Difference & Application

In electrical insulation, two paper materials often cause confusion: Electrical cable paper and Insulation presspaper. While both serve critical roles in protecting electrical systems, they have distinct properties and applications. At PaperInsulation.com, we specialize in both materials and frequently guide clients in selecting the right paper for their specific needs.

This comprehensive comparison will clarify the key differences between cable paper and insulation presspaper, helping engineers, procurement specialists, and manufacturers make informed decisions for their electrical insulation projects."

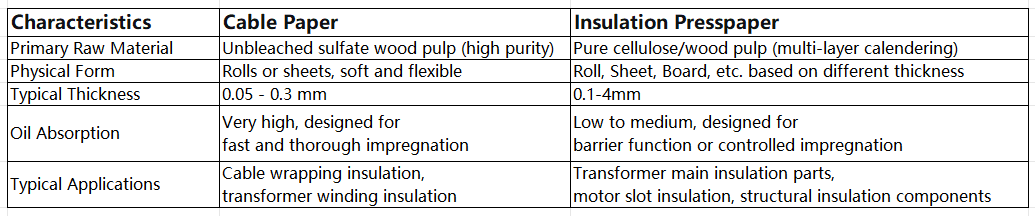

Characteristics of Cable paper and Insulation presspaper

Cable Paper is essentially a high-purity specialty paper. It is supplied in rolls, possessing excellent flexibility and wrap-ability, and is specifically designed for wrapping or lapping around conductors.

Insulation Presspaper is a dense laminated material. Its primary commercial form is rigid or semi-rigid sheets/boards of various thicknesses, known for high mechanical strength and dimensional stability. While thinner grades (e.g., below 1mm) may have some bendability, its main intended use and design purpose is as a structural component.

Electrical Cable paper is typically made from unbleached sulfate wood pulp using a long-wire papermaking process to ensure long fibers, high strength, and uniform pore distribution.

Thickness Range: Usually thin, between 0.05 mm (50 microns) and 0.30 mm (300 microns) to meet the flexibility requirements of cable wrapping and multi-layer insulation.

Dielectric Strength: Extremely high, typically ≥14 kV/mm or higher, effectively resisting electric field breakdown.

Porosity and Oil Absorption: Possesses a controllable and uniform porous structure with high oil absorption (oil absorption height typically >30 mm/10 min), allowing for rapid and thorough impregnation with insulating oil to form a complete oil-paper insulation system.

Mechanical Properties: Has good longitudinal tensile strength and excellent folding endurance to accommodate cable bending and manufacturing processes.

Purity and Chemical Stability: Extremely low ash content (typically <0.8%), neutral pH, and few conductive particles, ensuring long-term stable electrical performance.

Advantages and Limitations:

Advantages: Excellent electrical strength, good impregnation performance, cost-effectiveness, good flexibility and easy processing.

Limitations: Relatively lower mechanical strength (especially radial) than pressed paper, performing poorly in purely dry applications or applications requiring extremely high mechanical support.

Insulating pressed paper, commonly known as transformer pressed paper or insulating board, is a dense, rigid plate-like material formed by pressing multiple layers of paper blanks together under high temperature and pressure. Its manufacturing process (pressing process) is key to its high performance, giving the material excellent mechanical and electrical properties.

Thickness and Density: Wide thickness range, from 0.5 mm to 3.0 mm or even thicker. After pressing, it has extremely high density (typically >1.0 g/cm³), a dense structure, and extremely low porosity.

Mechanical Strength: Exquisite mechanical properties, with extremely high tensile, compressive, and shear strength. Excellent dimensional stability, and resistant to deformation under varying temperature and humidity.

Dielectric Strength: Also possesses high dielectric strength (≥12 kV/mm), but due to its high density, its partial discharge initiation voltage (PDIV) is typically higher.

Oil Absorption and Resistance: Low and controllable oil absorption, primarily acting as a barrier to prevent excessive penetration or migration of insulating oil. In some applications, it can also be designed as an impregnable type.

Processability: Allows for precise stamping, cutting, drilling, and forming.

Advantages and Limitations:

Advantages: Unparalleled mechanical strength and stiffness, excellent dimensional stability, good moisture and oil resistance, and excellent long-term thermal aging performance.

Limitations: Higher cost, poor flexibility, generally unsuitable for wrapping applications requiring tight bending.

Choose Cable Paper for:

Impregnated winding insulation: Such as oil-immersed transformer windings, interlayer insulation of reactors.

Flexible wrapping insulation: Such as conductor insulation of power cables and communication cables.

High dielectric strength priority: Maximizing electrical insulation strength within a limited space.

Cost-sensitive mass production: For example, the manufacture of standard specification cables.

Choose insulation press paper for:

Insulation structures requiring mechanical support: Such as transformer baffles, spacers, corner rings, slot liners and slot wedges in motors.

Dry-type or dimensionally stable insulation: Insulation components requiring extremely low deformation rates in dry-type transformers or equipment.

Barrier insulation in high-voltage equipment: Needed to prevent oil flow or serve as a primary insulation barrier, such as baffles in switchgear.

Insulation components requiring precision machining: Insulation components need to be stamped, cut into complex shapes, and maintain precision.

Mixed Application Scenarios: In large oil-immersed transformers, cable paper and insulating pressure paper are often used together, leveraging their respective strengths:

Cable paper is used to wind around the coil conductors, providing excellent interlayer insulation and oil channels.

Insulating pressure paper is made into corner rings, support bars, and partitions to provide robust mechanical support and primary insulation barriers between coils and between coils and the core. This combination achieves a perfect balance between electrical performance and mechanical structure.

Application

Uses for Electrical Cable Paper: Serves as the main insulation layer on conductors in oil-immersed transformers, high-voltage power cables, and bushings. It always works in synergy with an impregnating agent (oil or resin) to form a composite oil-paper insulation.

Uses for Insulation Presspaper: Used to manufacture structural insulating components, such as motor slot wedges, transformer barriers and spacers, insulating end rings, terminal boards, etc. It provides physical support, separation, and insulation.

Cable Paper is like high-tech insulating fabric—it is the functional wrapping layer that provides basic protection.

Presspaper is like the reinforcing insert in a backpack or an insole—it provides shape, support, and rigidity to the entire structure, while itself possessing insulating properties. A thinner insert can bend, but it is never used for wrapping.

Conclusion

Although both electrical cable paper and insulation presspaper are derived from cellulose, they are engineering materials designed for different applications. Cable paper is used as an insulating wrapping layer for conductors, while pressed paper is used as an insulating structural component in equipment. The most reliable way to choose is to work closely with your insulation material supplier. Provide detailed application parameters (such as voltage rating, temperature, mechanical stress, and dielectric environment), and experienced suppliers (such as PaperInsulation) can recommend the most suitable and economical material solution based on these standards and their technological expertise.

Quick Quote