The Difference Between G10 and FR4 Fiberglass-epoxy Laminated Board

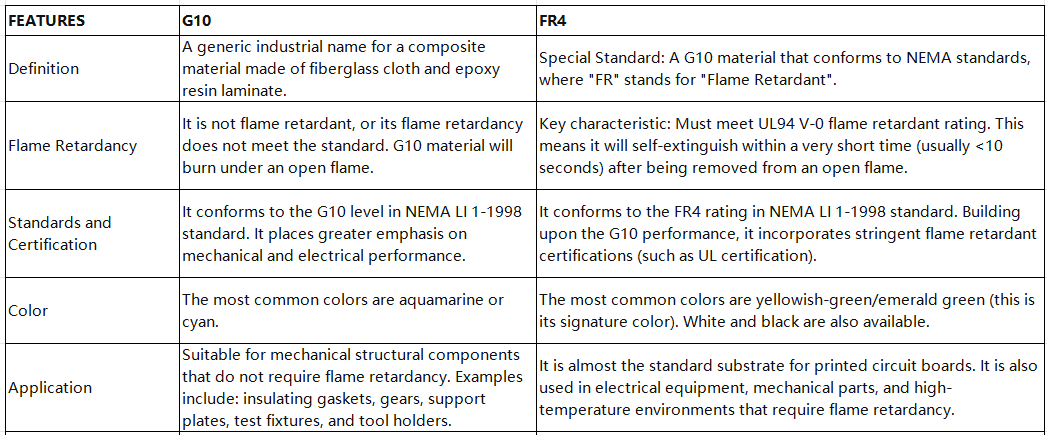

In the electronics and engineering fields, these two insulating materials, G10 and FR4, are frequently encountered. G10 and FR4 epoxy fiberglass boards are closely related but have clear differences. Simply put: FR4 is a subset of G10, specifically a G10 material that meets certain flame-retardant standards.The following table and detailed explanation illustrate their differences and connections:

Detailed Explanation of G10 and FR4:

1. Relationship

G10: A general industrial name for a composite material made of fiberglass cloth and epoxy resin laminate. It is known for its extremely high mechanical strength, excellent electrical insulation, good moisture resistance, and processability.

FR4: An abbreviation for "Flame Retardant 4". It is a specific grade of G10 material, achieved by adding flame retardants such as brominated epoxy resin to meet stringent flame retardant standards (UL94 V-0).

2. Flame Retardancy – The Most Critical Difference

This is the core difference between the two in application:

G10 will continue to burn in a flame, producing smoke.

FR4 is designed to self-extinguish rapidly once removed from an open flame, a fundamental safety requirement for electronic products to prevent fires caused by circuit failures.

3. Application of G10 and FR4

G10 Applications: In applications requiring high mechanical performance but without fire risk.

Electrical insulation gaskets, brackets

High-performance gears (especially in humid environments)

Model making, tool holder materials

Structural components requiring insulation and strength

FR4 applications:

Absolutely dominant field: Printed circuit boards. The vast majority of computer motherboards, mobile phone motherboards, and various control boards we see use FR4 substrates.

Electrical housings requiring flame retardancy, switch panels.

Mechanical components requiring both strength and fire resistance.

4. Physical Properties (Similarities and Differences)

Similarities: In terms of mechanical strength (bending resistance, impact resistance), electrical insulation, chemical resistance, and machinability (drillable, millable, shearable), FR4 inherits all the advantages of G10.

Differences:

Flame retardancy: As mentioned above, this is the fundamental difference.

Color: FR4's signature yellow-green comes from the brominated epoxy resin it uses. G10, on the other hand, is typically aquamarine.

Thermal stability (Tg value): FR4 comes in different types depending on the resin formulation, including standard Tg (approximately 130-140°C), medium Tg, and high Tg (>170°C) to meet various soldering temperature requirements. General-purpose G10 typically doesn't emphasize Tg values.

Dielectric constant: For high-frequency PCB applications, specially formulated FR4 (such as FR-4 high-frequency version) is used, offering superior dielectric constant and loss factor. General-purpose G10 may not have stricter control over these aspects.

Summary and purchasing recommendations: If you need to manufacture circuit boards or any insulating components involving circuitry or electrical components, FR4 must be chosen. This is a mandatory requirement due to safety regulations and product certifications.

If you are only manufacturing mechanical parts, models, insulating fixtures, etc., and there is absolutely no fire risk, choosing G10 is usually more cost-effective, as you don't need to pay extra for flame-retardant properties.

When purchasing, directly observing the color is a quick and easy way to distinguish between yellow-green and aquamarine, but the most reliable method is to check the material's data sheet or certification documents to confirm whether it complies with the UL94 V-0 standard.

Quick Quote