Xuchang Chengrui Insulation Materials Co., Ltd.

Henan Province, China

SEND SMS

Leading Manufacturer & Exporters of different types insulation film, such as polyester film,mylar film,polymide film,polyester film roll, clear mylar roll, clear polyester film, polymide film tape, etc. They are most used for making insulators, electrical winding insulation, winding wire coating insulation, electrical base, shell, motor, switch baseplate, etc. All the electrical insulation materials can be custom according to your need.

Polyester Film 6021 Product Details:

6021 PET polyester film or mylar electrical insulation sheets, or mylar polyester film is made of PET molten and biaxial directional drawing. The 6021 polyester film has good insulation performance and excellent mechanical properties. It is a widely used electrical insulation film and can be used to produce soft composite material, wire wrap, electronic electrical insulation gasket, motor groove, inter-turn insulation, and print, etc.

Additional Information

Type: Insulation Film

Insulation class: E (120°C)

Thickness: 0.125mm, 0.188mm, 0.25mm, 0.30mm, 0.35mm

Width: 1000mm or customized

Form: in rolls

Color: milky white

Application: Insulators, Electrical Winding Insulation, Electrical Base, Shell, Motor, Switch Baseplate, Solar Back Sheet and Package

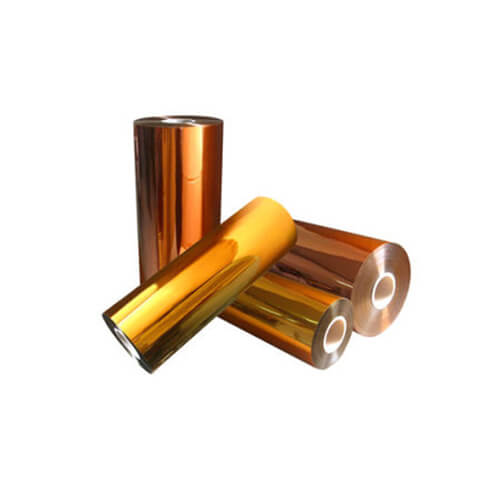

Polymide Film 6051 Product Details:

6051 polyimide film or polyimide film sheet is one of the electrical insulation film. It is synthesized by polymerizing PMDA and ODA in strong polar solvents through the process of forming film and imines treatment at high temperatures. This insulation product has excellent mechanical capability, favorable electric insulation at temperatures as low as -452F(-269c) and as high as +752F(+400c). It can be used in compound insulation material, adhesive tape, electric wire, and motor industry, etc.

Additional Information

Type: Insulation Film

Insulation class: H (180℃)

Thickness: 0.05mm, 0.075mm, 0.1mm

Width: 1000mm or as request

Color: golden

Application: Used in flexible printed circuits and as insulating materials of flat electric cables, electromagnetic wires and motors

Chengrui's insulation film delivers reliability without compromise. As a trusted insulation film manufacturer, we understand that your applications demand more than just basic dielectric properties—they need materials engineered for real-world performance. Our polyester film solutions combine high dielectric strength with mechanical durability, whether you require standard clear polyester film for visibility or specialized adhesive mylar film for secure bonding.

At Chengrui polyester film factory, we craft insulation films that solve real problems in your electrical systems. When you need polyester PET film that won’t degrade under heat or humidity, our films provide stable dielectric performance without compromising flexibility. Whether you’re unrolling a polyester film roll for motor insulation or layering polyester lamination film for multilayer PCBs, our materials deliver consistent thickness and puncture resistance—because downtime from film failure isn’t an option for your operations.

When precision insulation matters, Chengrui stands as a trusted insulation film manufacturer with solutions tailored to your toughest electrical challenges. Our polyester film range, including high-clarity mylar polyester film and versatile polyester PET film, delivers reliable dielectric protection for everyday applications. Need heat resistance? Our Polymide Film withstands extreme temperatures up to 220°C, making it ideal for aerospace or automotive electronics.

As leading polyester film suppliers and Polymide Film suppliers, we ensure every polyester film roll meets exacting standards. Whether you’re layering polyester lamination film for flexible circuits or insulating transformers with our Polymide Film, our materials combine durability with easy handling. The smooth surface of our films prevents air bubbles during application, while consistent thickness guarantees uniform insulation across your production line.

From consumer electronics to heavy industrial equipment, Chengrui’s films adapt to your needs without compromising performance. We don’t just supply materials—we engineer solutions that reduce waste, streamline installation, and extend the lifespan of your components. When your insulation can’t fail, trust a manufacturer that builds reliability into every layer.

When your project demands precision-engineered insulation films, settling for generic materials isn’t an option. As a seasoned insulation film manufacturer, Chengrui delivers more than just polyester film rolls—we provide engineered solutions. Our polyester PET film offers unmatched dielectric consistency, while our mylar polyester film ensures optical clarity without sacrificing protection. Need extreme heat resistance? Our Polymide Film outperforms competitors with 220°C endurance, all at a competitive Polymide Film price that doesn’t cut corners on quality.

Unlike suppliers who prioritize volume over reliability, every polyester film roll from our factory undergoes rigorous testing for thickness uniformity and tensile strength. We’ve optimized our polyester film price structure by streamlining production—not by compromising on raw materials. Whether you’re insulating flexible circuits or high-voltage components, our films lay flat without wrinkles, bond evenly, and resist degradation from oils or solvents.

Electrical insulation film selection requires careful consideration of multiple technical and operational factors. The process begins with understanding your specific application requirements rather than simply comparing product specifications. Different industrial applications demand distinct performance characteristics from insulation materials, making a one-size-fits-all approach ineffective.

Material compatibility forms the foundation of proper selection. Polyester films generally provide excellent dielectric properties for moderate temperature applications, typically performing well up to 150°C. For higher temperature environments exceeding 200°C, polyimide films become necessary despite their higher cost. The thickness of the film directly impacts both electrical performance and mechanical durability - thinner films allow for more compact designs but may compromise long-term reliability in high-vibration environments.

Environmental conditions significantly influence material performance. Applications exposed to moisture require films with strong hydrolytic stability, while outdoor uses need UV-resistant variants. Chemical exposure presents another critical factor, as certain solvents or oils can degrade standard polyester films over time. In such cases, specially coated or chemically resistant films become necessary.

Processing requirements often get overlooked during selection. Consider how the film will be handled during manufacturing - some materials work better with certain cutting, laminating, or bonding processes than others. The film's dimensional stability during processing can affect final product quality and manufacturing yield. Always request sample material to test in your actual production conditions before making bulk purchases.

Cost analysis should extend beyond the initial price per square meter. Consider the total cost of ownership, including waste during processing, potential rework costs from material failures, and the impact on production efficiency. Sometimes a slightly more expensive film that processes more efficiently actually reduces overall costs.

Supplier evaluation represents the final crucial step. Look for manufacturers with consistent quality control measures and proper certifications for your industry. Request material test reports and verify they conduct regular batch testing. Reliable technical support for application-specific questions often proves more valuable than minor price differences between suppliers.

Chengrui stand out as polyester film suppliers isn't just technical specs—it's how our films perform in your hands. The balanced thickness in our films resists wrinkling during installation while maintaining flexibility for tight spaces. Unlike generic options, our films maintain consistent dielectric properties across temperature fluctuations, preventing unexpected failures. For applications where clarity matters, our optically clear films allow visual inspection without sacrificing insulation integrity.

Every roll we produce meets rigorous quality checks because we know your projects can't afford inconsistencies. From automotive electronics to industrial motor insulation, our films provide that critical barrier against electrical leakage and environmental damage. When you need materials that work as hard as your equipment does, trust a manufacturer that prioritizes reliability over shortcuts.

As both a Polyimide Film manufacturer and polyester film manufacturer, we offer solutions tailored to your budget. Our competitive polyester film price reflects direct factory efficiency, not middleman markups. For high-temperature applications, our Polyimide Film outperforms standard PET film with 220°C+ thermal endurance, while our mylar polyester film combines optical clarity with reliable insulation for display components. Every formulation balances cost and performance—no over-engineering, no underspec’d compromises.

Your engineers will notice the difference: smoother edges on cut polyester film rolls, consistent adhesive bonding in polyester lamination film, and reliable dielectric strength batch after batch. We don’t just meet specs; we ensure our films install cleanly and last longer—because your success depends on materials that work as hard as you do.

When it comes to electrical insulation solutions, Chengrui has built its reputation as a trusted insulation film manufacturer through consistent quality and technical expertise. Our polyester film products offer excellent dielectric properties for general-purpose applications, while our high-performance Polymide Film withstands extreme temperatures for demanding environments. The mylar film variants in our portfolio provide exceptional dimensional stability where precision matters most.

We understand that insulation film price is just one factor in your purchasing decision. That's why we focus on delivering value through material consistency, with every insulation film roll meeting strict thickness tolerances and electrical specifications. Our production processes ensure batch-to-batch reliability, reducing waste and rework in your operations.

Backed by rigorous testing protocols and responsive technical support, Chengrui helps engineers and procurement specialists make informed material selections without compromise. Whether you need standard polyester solutions or specialized high-temperature films, our manufacturing capabilities deliver the right balance of performance and cost-efficiency.