F-grade Electrical Insulation Paper for Motors Specs and Applications

At the heart of every reliable electric motor lies a sophisticated insulation system, where composite insulation papers serve as the first line of defense. Among these engineered materials, F-grade electrical insulation paper has emerged as industry standards, balancing performance, durability, and cost-effectiveness. These aren't simple papers but carefully designed laminates where each layer contributes specific properties to create a material greater than the sum of its parts. Understanding their construction, specifications, and optimal applications is essential for designing motors that deliver consistent performance across demanding industrial environments.

Among numerous insulating materials, there are two major F-grade insulation materials in the field of motor insulation due to their excellent performance balance. Today, we will delve into the mysteries of these two materials to help you make an informed choice in practical applications.

DMD electrical insulation paper and NMN electrical insulation paper

Chapter 1: Deciphering the Structures of DMD and MNM

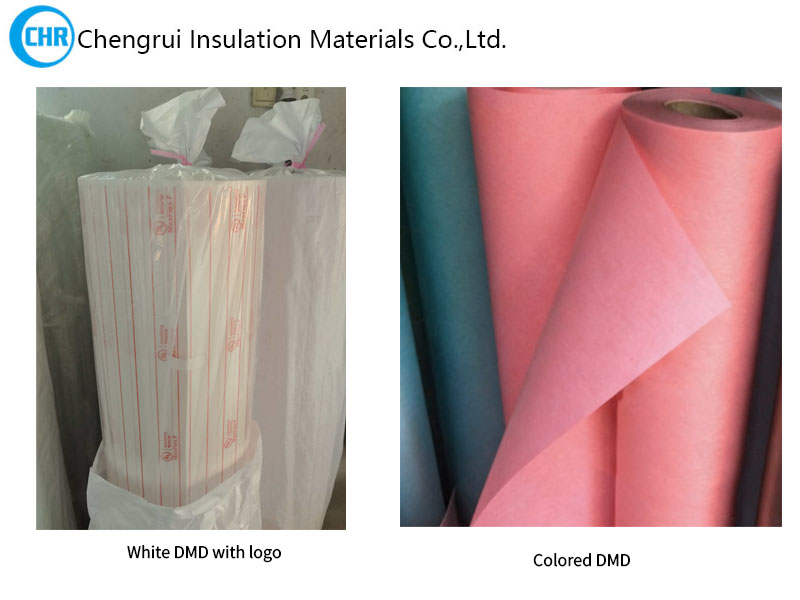

DMD: A Cost-Effective Choice Based on Polyester

The structure of DMD is as its name suggests—a three-layer symmetrical design:

Outer Layer D: Polyester nonwoven fabric (thickness 0.05-0.10mm)

Middle Layer M: Polyester film(Mylar film)

Inner Layer D: Polyester nonwoven fabric

This structure cleverly combines the mechanical strength of nonwoven fabric with the electrical properties of film. The polyester fiber layer provides excellent tear resistance and flexibility, making the material less prone to damage during automatic winding; the middle PET film contributes excellent dielectric strength and moisture resistance.

Manufacturing Process: Utilizing hot-pressing lamination technology, the three layers are firmly bonded together using a thermoplastic adhesive at a temperature of 120-150°C and a pressure of 1-3MPa.

NMN: High-Performance Insulation Solution

NMN represents a higher performance insulation standard:

Outer Layer N: Nomex® Paper

Middle Layer M: Polyester film (Mylar film)

Inner Layer N: Nomex®Paper

Nomex® is a DuPont patented material made of aramid fibers, possessing inherent flame retardancy and high-temperature stability. The addition of the mica layer significantly improves its corona resistance, making it particularly suitable for inverter power supply applications.

Manufacturing Process: Impregnated with epoxy or silicone resin and cured at 180-200°C.

Chapter Two: Performance Comparison

Thermomechanical Performance Comparison

Thermal Stability Test (155°C, 1000 hours of aging):

DMD: Mechanical strength retention rate approximately 70%. NMN: Mechanical strength retention rate >85%

Case Study: A water pump manufacturer reported that in motors using DMD insulation, insulation embrittlement began to occur after 3 years when operating temperatures exceeded 140°C. After switching to NMN, no significant aging was observed after 5 years of operation under the same conditions.

Chemical compatibility:

Both are resistant to transformer oil and lubricating oil.

NMN has better resistance to refrigerants and weak acids and alkalis.

Chapter Three:Application of DMD and NMN electrical insulation paper

When to Choose DMD?

1: Cost-Sensitive Mass Production

"In a project producing 100,000 household air conditioner compressor motors annually, we chose 0.15mm DMD as the slot insulation material. Compared to NMN, the cost per unit is reduced by approximately 2.5 yuan, resulting in annual cost savings of 2.5 million yuan, while fully meeting product lifespan requirements." — Technical Director of a home appliance company

2: Standard Industrial Environment

Voltage Rating: ≤690V

Ambient Temperature: -20°C to 155°C

Humidity Requirement: Relative Humidity ≤85%

Typical Applications: General equipment such as fans, pumps, and conveyor belts

Recommended Configuration:

Slot Insulation: 0.15-0.20mm DMD

Phase-to-Phase Insulation: 0.25mm DMD

Manufacturing Process: VPI impregnation or drip coating process

When to Choose NMN?

1: Motor Powered by a Frequency Converter

"Our mine hoist uses frequency converter control. Initially, it used DMD insulation, which developed inter-turn short circuits after two years of operation. After switching to NMN, it has maintained good performance for five years. Corona resistance is key!" — A mine equipment maintenance engineer

2: High Voltage and Harsh Environment

Voltage Rating: 690V-10kV

Ambient Temperature: May exceed 155°C

Presence of corrosive gases or liquids

Certification Requirements: ATEX, UL, etc.

Recommended Configuration:

Inter-turn Insulation: 0.08mm NMN

Main Insulation: 0.18-0.25mm NMN

Special Treatment: Edge reinforcement, anti-corona coating

Chapter Four: Cutting-Edge Technology – Future Development Trends

The Evolution of Next-Generation DMD:

Nano-Reinforced: Adding nano-alumina improves corona resistance by 3 times.

High Thermal Conductivity: Thermal conductivity increased to 0.25 W/(m·K), aiding in motor heat dissipation.

Bio-Based and Environmentally Friendly: Using renewable raw materials, reducing carbon footprint by 40%.

NMN Technological Breakthroughs:

Low-Temperature Curing: Curing temperature reduced from 200°C to 130°C, resulting in significant energy savings.

Self-Diagnostic and Intelligent: Integrated sensors monitor insulation status in real time.

Ultra-Thin and High-Strength: Maintaining integrity performance with a thickness of 0.05 mm.

Choosing between DMD and NMN is never a simple binary decision. It requires comprehensive consideration of:

Technical factors: voltage, frequency, temperature, environment

Economic factors: initial cost, operating cost, maintenance cost

Strategic factors: product positioning, market requirements, supply chain security

A senior motor designer once said, "The best insulation material is not the one with the strongest performance, but the one that is most suitable."

In today's rapidly evolving motor technology, insulation materials are also constantly improving. Regardless of the material chosen, the key is to establish a systematic selection method, a rigorous verification process, and a comprehensive quality control system.

Quick Quote