NHN Insulation Paper: H-Class Performance for Demanding Applications

In the electrical and industrial equipment sector, reliability is paramount. Ensuring the durability and safety of equipment in harsh environments hinges on a crucial insulating material: NHN insulation paper – a composite paper made from Nomex paper and polyimide film.

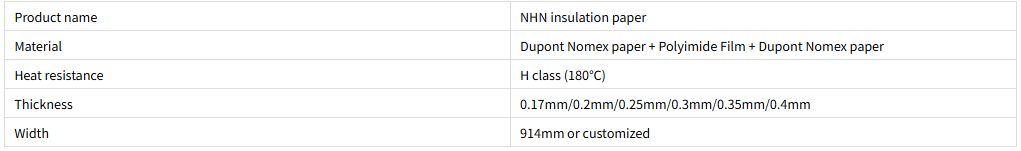

NHN insulating paper, a high-performance composite insulating material, is made by hot-pressing polyimide film and two sides of Nomex paper (meta-aramid paper) with H-class adhesive. It possesses H-class heat resistance (180℃), excellent mechanical strength, and electrical properties, and is widely used in industrial fields with stringent insulation requirements.

I. Core Insulation for Power Equipment

NHN insulating paper is a key material in H-class motor insulation systems, used for slot-to-slot, turn-to-turn, phase-to-phase, and slot cover insulation. Its smooth surface allows for compatibility with automated production lines, ensuring production efficiency. For example, in the drive motors of new energy vehicles, NHN, with its tear resistance (edge tear resistance ≥8N) and high-temperature resistance, can withstand the mechanical stress and heat generated by high-speed operation. Furthermore, its high compatibility with insulating varnish effectively improves the overall insulation reliability of the motor.

In dry-type transformers, NHN serves as the interlayer insulation material. It can withstand long-term high temperatures of H Class 180℃ and provides a breakdown voltage of ≥8KV (0.25mm thickness), ensuring electrical isolation between layers. Compared to traditional materials, it is thinner (0.14-0.47mm), achieving efficient insulation within limited space while reducing equipment weight.

II. Industrial and Special Equipment Applications High Environmental Adaptability Equipment

1. Explosion-proof Motors: In flammable and explosive environments such as petrochemical plants, NHN's flame retardancy (UL 94 V-0 rating) and chemical stability (oil and coolant resistance) ensure safe equipment operation.

2. Rail Transit Traction Systems: Traction motors and transformers in high-speed trains need to withstand vibration and high temperatures; NHN's tear resistance and thermal stability meet long-term reliability requirements.

3. Aerospace: Although AHA and other ultra-H grade materials are more common, NHN is still used in some aircraft motors and transformers. Its lightweight and high-temperature resistance properties can optimize the performance of aerospace equipment.

III. New Energy and Renewable Energy

Electric Vehicles and Charging Stations

1. Drive Motor Insulation: In electric vehicle motors, NHN can withstand the high temperatures and electromagnetic interference generated by frequent charging and discharging, improving motor efficiency and lifespan.

2. Battery Pack Insulation: Some high-voltage battery modules use NHN as interlayer insulation to prevent short circuits and isolate battery heat.

3. Wind and Solar Power Generation: In the gearbox motors of wind turbines and the transformers of photovoltaic inverters, NHN can withstand complex outdoor environments (such as humidity and ultraviolet radiation) while meeting H-grade heat resistance requirements, reducing maintenance costs.

Quick Quote