Insulation Paper for Motor Winding Price

If you're sourcing motor winding insulation paper, you've likely encountered a wide and confusing range of prices. The issue isn't simply "How much will it cost?", but rather "What drives the cost of this critical component?" The price of motor insulation paper isn't arbitrary; it directly reflects the level of materials, performance, and engineering invested to ensure the reliability and lifespan of the motor.

Understanding these factors will enable you to make informed purchasing decisions, balancing your budget with the technical requirements of your application. Let's delve into the key elements that determine the final invoice amount.

1. Material Composition: The Core Cost Driver

Material type is the most significant factor influencing price. Insulation paper isn't a one-size-fits-all solution; its cost varies considerably.

Economy Option: DMD insulation paper (Nonwoven Fabric-Polyester Film-Nonwoven Fabric Composite Materiel)

Price Range: Low to Medium

Reasons for this: DMD is the industry mainstay. Its components—polyester film and polyester nonwoven fabric—are widely produced and relatively inexpensive. For standard motor applications (e.g., industrial motors, fans, pumps), it offers an excellent balance between electrical, mechanical performance, and economic benefits. For Class B (130°C) and Class F (155°C) insulation systems, DMD is typically the most cost-effective option.

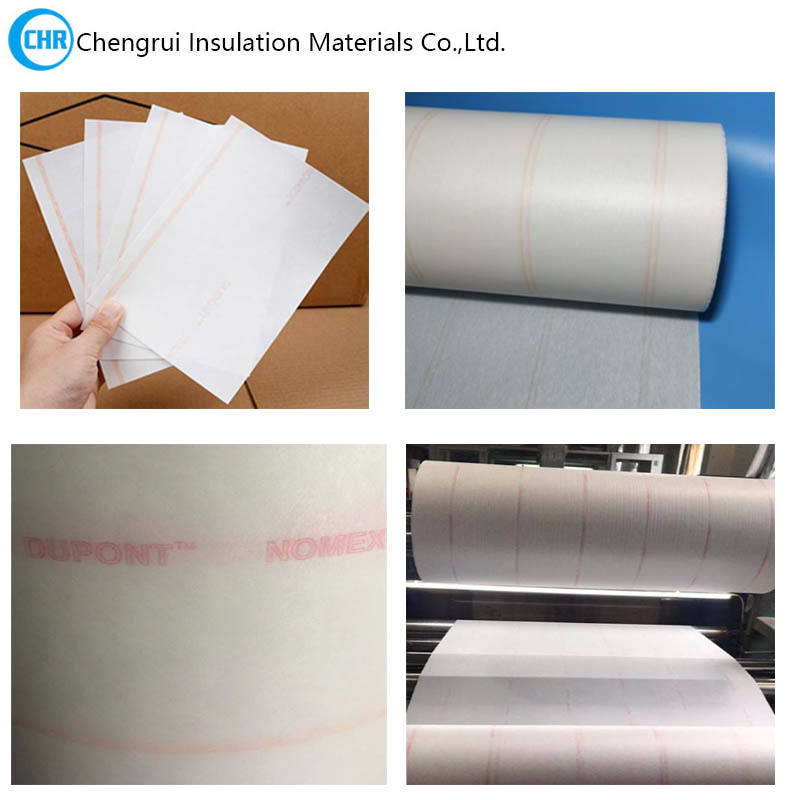

High-Performance Options: NMN insulation paper, Aramid Paper (e.g., Nomex®)

Price Range: Mid to High

Reason: Aramid-based materials (such as NMN) become the answer when applications require higher heat resistance (Class H, 180°C or Class C, 220°C) or superior mechanical and chemical resistance. The production cost of aramid fibers is inherently higher than that of polyester, a cost passed on to consumers. These materials are crucial for demanding environments, such as electric vehicle traction motors, high-efficiency generators, or motors in harsh chemical plant environments.

Specialty and Composite Materials

Price Range: High to High

Reason: Materials containing mica to provide superior partial discharge resistance, or those combined with other high-performance films, are expensive. They are designed for specific, often extreme, operating conditions, such as high-voltage motors or aerospace motors.

2. The "Prepreg" Premium: Paying for Performance

Standard DMD or NMN are the base materials. When you choose a prepreg version, you are adding significant value and cost.

What is prepreg? These materials are pre-impregnated with a Class B thermosetting resin (e.g., epoxy). They dry and are stable at room temperature until heated during the motor's curing process.

Why the Higher Price? The additional manufacturing steps of precise resin impregnation and localized curing increase production costs. However, this premium gives you a highly reliable insulation system. The resin flows and cures during manufacturing, bonding the insulation paper to the windings and core, forming a monolithic, gapless structure. This enhances mechanical strength, thermal conductivity, and moisture resistance, ultimately reducing the risk of failure and extending motor life.

3. Technical Specifications: Thickness, Width The physical dimensions of insulating paper directly affect its price.

Thickness: Thicker paper uses more raw materials and is therefore more expensive. Common thicknesses such as 0.13mm, 0.18mm, and 0.25mm will have different prices per square meter.

Width and Slitting: Standard widths are more economical. If you require non-standard custom widths, manufacturers may charge extra due to mold setup and lower production efficiency.

4. Quantity and Supply Chain Logistics

This is a fundamental principle in manufacturing: volume is key.

Order Quantity: Buying large quantities, such as a 40-foot container, is always cheaper than buying smaller slits. For large motor manufacturers, bulk purchasing is the only way to remain competitive.

Suppliers and Brands: Reputable, well-known brands with a good track record in quality control may charge higher fees than lesser-known suppliers. However, this usually comes with guarantees of material consistency and reliability, which are crucial for motor performance.

Global Factors: Raw material costs (e.g., the supply of petrochemicals used to produce polyester and aramid fibers) are affected by global market fluctuations. Logistics and tariffs also play a role in final landed costs.

How to Choose Motor Winding Paper Between Price and Performance: Choosing the cheapest option can be one of the most costly mistakes you can make. A poorly performing insulation system can lead to premature motor failure, resulting in costly downtime, repair expenses, and reputational damage.

Here's a simple decision-making framework:

Define your motor insulation class: What heat resistance class (B, F, H) is required? Using Class B materials in a Class F design is a root cause of failure.

Assess the operating environment: Is the motor exposed to moisture, chemicals, or severe vibration? In such cases, the enhanced protection provided by prepreg NMN may justify its higher initial cost by preventing future failures.

Understand the manufacturing process: If you are using a VPI (vacuum pressure impregnation) process, standard non-prepreg materials may be sufficient. For drip impregnation processes or situations requiring a robust structure, prepreg is often a worthwhile investment.

Calculate the total cost of ownership: Go beyond the price per kilogram. Consider the reliability, energy efficiency, and lifespan offered by a high-quality insulation system. A slightly more expensive insulating paper that improves the mean time between failures is an investment, not a cost.

The price of motor winding insulation paper is a complex equation comprised of material, performance, and quantity. From economical and durable DMD to high-temperature resistant NMN, and prepreg materials with integrated performance, each option serves a specific purpose at a corresponding price point.

By understanding what value you get for your money, you can go beyond simple price comparisons. You can strategically choose insulation paper that offers the best balance between performance, durability, and value, ensuring that the motors you manufacture or maintain run stronger and longer.

Quick Quote