Get the Best Deal from China Insulation Pressboard Suppliers

Securing the best price-performance ratio for insulation pressboard from Chinese suppliers involves more than just haggling over the unit price. It requires market insight, strategic negotiation, and a focus on building strong, long-term partnerships. While cost is always a key factor, seasoned importers know that true value comes from optimizing the entire supply chain—from quality assurance and production planning to logistics and payment terms.

Start with Smart Market Research

A well-informed buyer holds a significant advantage in any negotiation. Before you begin discussions with potential suppliers, take the time to understand the market dynamics that influence pricing.

Track Raw Material Costs: The price of insulation pressboard is directly tied to pulp costs. Monitoring the China Softwood Pulp Index (CSPI) provides valuable leverage for negotiating price adjustments.

Time Your Contracts: Most manufacturers review and adjust their prices quarterly. Aim to time your major contract renewals for March or September to align with these cycles and secure more stable pricing.

Be Flexible on Tolerances: Strict technical specifications can drive up costs. For instance, agreeing to a standard thickness tolerance of ±0.05 mm instead of demanding ±0.02 mm can reduce your costs by 8-12% without sacrificing functional performance.

Master the Art of Negotiation

Move beyond the initial quote by negotiating on terms that create mutual benefits.

Payment Terms: A 30% wire transfer deposit is standard, but this can often be negotiated down to 20% for buyers with a history of stable, high-volume orders. For orders exceeding $80,000, explore options like sight Letters of Credit. Established distributors with a 24-month relationship may even qualify for credit terms.

Production Scheduling: Rushed orders come with a premium. While 15-day emergency deliveries incur high fees, planning for a 60-day production cycle can earn you a 10-15% discount as it allows the supplier to optimize their production schedule.

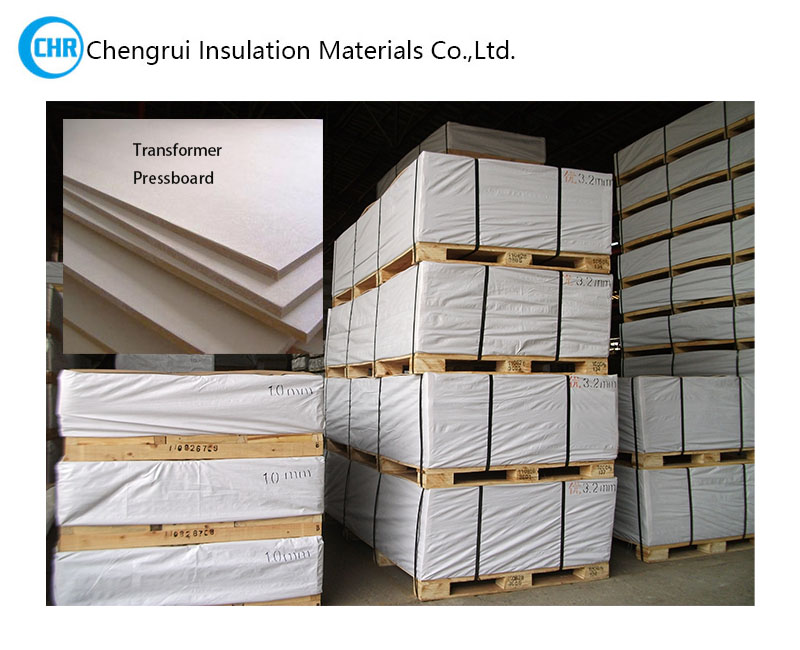

Consolidate for Savings: Significant economies of scale can be achieved through consolidated purchasing.

Combine orders for different thicknesses (e.g., 1mm, 2mm, 3mm) in a single production batch to secure a 7-9% bulk discount.

Partner with other non-competitive importers to meet factory Minimum Order Quantity (MOQ) requirements, unlocking better pricing for all parties.

Optimize Logistics and Packaging

Often-overlooked areas like packaging and shipping can yield additional savings and efficiency.

Packaging Innovation: Switching from heavy, custom wooden crates to standardized moisture-proof pallets can reduce shipping costs by 3-5%. This simpler packaging also tends to attract less attention during customs inspections, minimizing potential delays.

Never Compromise on Quality Assurance

Cost-cutting should never come at the expense of product integrity. A robust quality assurance process is non-negotiable.

Always insist on a batch-specific test report that includes:

Dielectric Strength: Measured using the ASTM D149 standard.

Thermal Aging Test: Conducted in accordance with IEC 60216.

Oil Immersion Verification: Request a video to visually confirm performance.

For added security, negotiate to include a free pre-shipment inspection by a third-party agency like SGS or Bureau Veritas in your contract. For container-sized orders, many manufacturers will absorb this cost (typically $300-$500).

Build Strategic Partnerships for Long-Term Value

The most significant advantages often come from long-term, collaborative relationships with your suppliers.

Loyalty Programs: Many factories now offer programs that provide:

Up to a 5% annual sales discount.

90 days of free storage in bonded warehouses.

Priority access to new, high-performance product grades.

Exclusive Distribution: Consider proposing an exclusive distribution agreement for your region. In exchange for market commitment, mid-sized factories often provide preferential pricing and dedicated support.

Your Action Plan for Success

To secure the best deal from a Chinese insulation pressboard supplier, follow this checklist:

1. Compare & Contrast: Obtain multiple quotes, but look beyond the price. Scrutinize payment terms, lead times, and quality certifications.

2. Negotiate Strategically: Use your market knowledge, order volume, and potential for a long-term relationship as leverage.

3. Verify Quality: Prioritize suppliers with verifiable quality control processes and insist on test reports and third-party inspections.

4. Test Before You Invest: Always request production samples for your own rigorous testing before placing a large order.

5. Go Direct: When possible, work directly with the manufacturer to eliminate middleman markups and improve communication.

To secure the best deal from Chinese insulation press board suppliers, compare prices by obtaining multiple quotes, negotiate based on quantity and long-term cooperation, and prioritize suppliers with quality certifications to avoid hidden costs.

Quick Quote