Silicone vs. Acrylic Insulation Sleeving

In the demanding world of electrical engineering and manufacturing, component longevity and system safety hinge on reliable insulation. Choosing the correct electrical insulation sleeving material for high-temperature applications is not just a design preference; it is a fundamental safety and performance requirement.

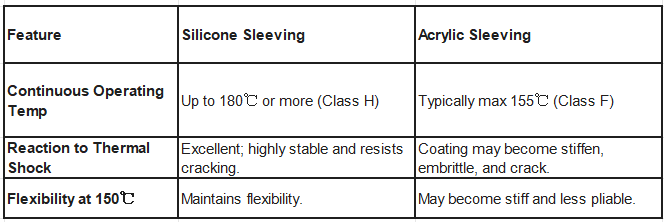

Two of the most dominant materials used to sheath and protect wires and cables under intense heat are Silicone-coated fiberglass sleeving and Acrylic-coated fiberglass sleeving. While both are engineered to withstand heat, their core chemistry dictates profoundly different performance profiles. This comprehensive guide will provide a technical, in-depth comparison of these materials, covering thermal limits, mechanical integrity, and cost-effectiveness, to help you make the best choice for your high-temperature application.

Silicone Sleeving: The Flexible Powerhouse

Silicone sleeving utilizes a silicone rubber coating applied over a braided fiberglass substrate. The performance advantage of silicone stems directly from its unique chemical backbone. This inorganic structure provides superior thermal stability and UV resistance compared to carbon-based polymers.

Key characteristics that make silicone sleeving the premium choice include:

Exceptional Flexibility: Remains highly elastic and flexible, even at extreme temperatures (both high and low).

Thermal Class: Typically rated to Class H (180℃), with specialized compounds reaching Class C (200℃ or higher)

Arc and Corona Resistance: Exhibits outstanding resistance to high-voltage discharge, reducing the risk of tracking.

Acrylic Sleeving: The Dielectric Specialist

Acrylic sleeving is produced by applying an acrylic resin varnish to a fiberglass braid. The acrylic coating is a type of thermoplastic that is prized for its electrical properties. It is often chosen as a cost-effective alternative where the absolute highest temperature resistance is not the primary constraint.

Key characteristics of acrylic sleeving include:

High Dielectric Strength: Offers superior initial resistance to electrical breakdown compared to standard uncoated sleeving.

Thermal Class: Commonly rated as Class F 155℃, or in some cases Class B 130℃.

Good Abrasion Resistance: The hard, tough nature of the cured acrylic coating provides strong mechanical protection.

High-Temperature Performance and Aging

The most critical factor in this comparison is how each material behaves under continuous high heat and thermal cycling.When exposed to temperatures significantly above its rating for extended periods, the acrylic coating undergoes thermal degradation, leading to a hard, brittle state. Once cracked, the underlying fiberglass braid is exposed, leading to a catastrophic loss of insulation integrity. Silicone, conversely, maintains its elastic properties far beyond the point where acrylic fails, making it ideal for systems with frequent temperature fluctuations (thermal shock).

Dielectric Stability under Heat

While acrylic sleeving typically boasts a higher initial dielectric strength at room temperature, this advantage diminishes rapidly as the temperature approaches its limit. The thermoplastic nature of the acrylic binder softens, causing a steep drop in its insulating capability and an increase in the dissipation factor.

Silicone, due to its stable inorganic structure, maintains a more consistent and predictable dielectric performance across its entire working temperature range. For applications where sustained high voltage isolation is needed in a very hot environment, silicone's stability is invaluable.

Flammability and Fire Safety

Safety standards often dictate the flammability characteristics of insulating materials.

Silicone: Is inherently self-extinguishing and often meets stringent flammability standards like UL VW-1 without extensive additives. When it does combust, it leaves behind a non-conductive silica ash, which can momentarily preserve some degree of electrical separation.Acrylic: Requires fire-retardant additives to meet VW-1 standards. Furthermore, burning acrylic releases more smoke and potentially more toxic fumes than silicone, which is a major consideration in closed environments (e.g., transit vehicles, aircraft).

Application, Installation, and Economics

The final selection often boils down to a balance between performance needs, mechanical handling, and budget.

Choose Silicone Sleeving when:

The operating temperature exceeds 155℃. Flexibility and bending during installation or operation are required (e.g., motor leads, coil windings).High-power transients or severe thermal cycling are present (e.g., aerospace, automotive exhaust systems, commercial cooking equipment).

2. Choose Acrylic Sleeving when:

The operating temperature is stable and reliably below 150℃. High initial dielectric strength is prioritized, and the material needs to withstand moderate abrasion (e.g., transformer manufacturing, standard appliance wiring).Cost is the dominant constraint for mass-produced goods.

Mechanical and Chemical Considerations

Abrasion Resistance: The rigid, cured acrylic coating provides better cut-through and abrasion resistance against sharp edges or friction during installation than the softer silicone rubber.

Chemical Resistance: Silicone offers broader resistance to common industrial solvents, fuels, and oils, which is a significant advantage in automotive and industrial machinery. Acrylic may swell or degrade upon exposure to certain harsh chemicals.

Conclusion: Making the Right Engineering Decision

In the battle between silicone and acrylic sleeving for high-temperature applications, there is no single winner—only the optimal fit.The key decision points are clear: If your application demands extreme temperature endurance, exceptional flexibility, stability in thermal cycling, and superior safety from arc/flame, silicone is the definitive choice. If your application is temperature-stable, requires high initial dielectric strength, and budget is the primary driver, then acrylic offers a cost-effective, durable solution up to its 155℃ limit.

Engineers must always prioritize the most severe environmental factor—temperature, abrasion, or chemical exposure—when finalizing the material selection. By understanding the chemical and thermal distinctions detailed here, you can confidently specify the right sleeving to ensure the safety and longevity of your critical electrical systems.

Are you looking for a reliable supplier of electrical insulating sleeves to customize products for you? Contact our engineering experts today for samples and technical consultation.

Quick Quote