High Performance Epoxy Insulation Boards Comprehensive Analysis

In fields such as electrical insulation, electronics, and aerospace, high-performance epoxy resin insulation boards are crucial foundational materials. Among them, the 3240 epoxy fiberglass cloth board and the FR4 epoxy fiberglass cloth board are two of the most widely used and frequently compared types. While they may look similar, they possess key differences in performance and application. This article provides an in-depth comparison to help you select the optimal material for your specific project.

Overview: What Are They?

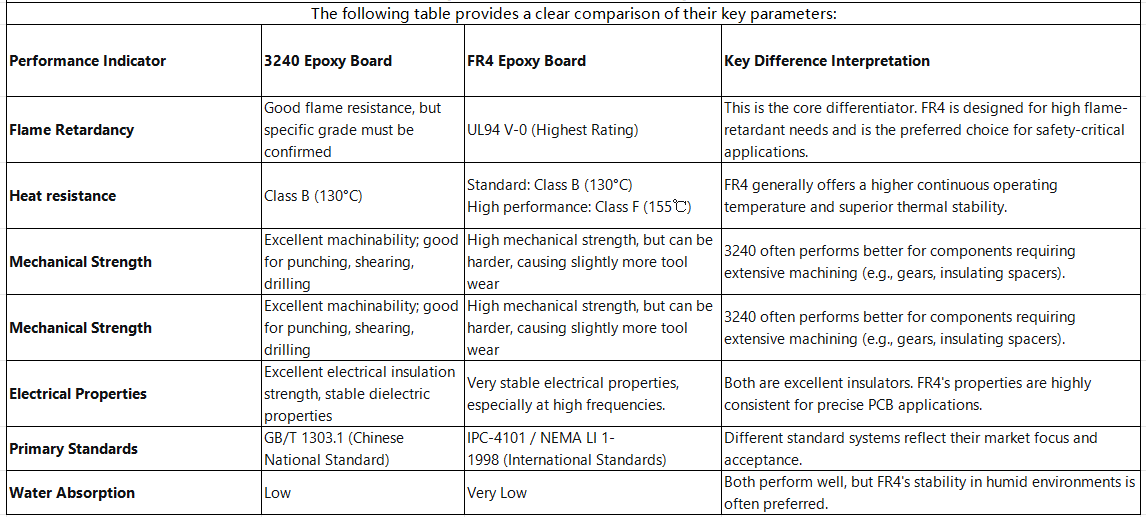

3240 Epoxy Board: This is a laminate made from electronic-grade fiberglass cloth impregnated with epoxy resin and thermally cured under pressure. It conforms to the Chinese standard GB/T 1303.1 and is renowned for its excellent electrical properties, mechanical strength, and heat resistance.

FR4 Epoxy Board: FR4 is essentially a grade designation, not a single material standard. It stands for "Flame Retardant 4" and also uses epoxy resin and fiberglass cloth. Its defining characteristic is that it must meet the UL94 V-0 flame retardancy rating. FR4 is a globally recognized standard, especially in the printed circuit board (PCB) industry.

In simple terms, all FR4 is an epoxy fiberglass board, but not all epoxy fiberglass boards (like 3240) inherently meet the FR4 flame retardancy standard.

How to Choose: 3240 or FR4?

The choice depends entirely on your specific application.

Choose 3240 Epoxy Board when your needs are:

★Industrial equipment requiring Chinese standard certification: Motors, electrical appliances, transformers targeting the domestic market.

★Components requiring extensive machining: Such as insulating structural parts in circuit breakers, gears, bushings, and gaskets. Its superior machinability improves production efficiency.

★General electrical insulation scenarios where flame retardancy is required but not at the highest level, such as slot insulation, terminal boards, etc.

Choose FR4 Epoxy Board when your needs are:

★Printed Circuit Boards (PCBs): This is the classic and primary application for FR4.

★High-reliability, high-safety equipment: Such as aerospace, military electronics, and medical devices, where the UL94 V-0 rating is often mandatory.

★Electrical equipment with high operating environment temperatures, such as variable frequency drives, high-power supplies, and servo drives.

Products for the global market requiring compliance with international standards and certifications.

Summary

In conclusion, both 3240 and FR4 epoxy insulation boards are top-tier epoxy insulation boards, each with its own focus.

3240 epoxy insulation board can be seen as an all-rounder: comprehensively capable, easy to machine, and cost-effective, particularly suited for structural insulation parts in the domestic industrial sector.

FR4 epoxy insulation board is a specialist: excelling in flame retardancy, heat resistance, and high-frequency stability, making it the cornerstone material for the global electronics industry and high-end electrical equipment.

Before making a final decision, always clarify your product's target market, safety certification requirements, operating environment, and manufacturing processes. With this comparison, we hope you can cut through the confusion and precisely select the most suitable high-performance epoxy insulation board for your project.

Quick Quote