Heat Resistance Grade of Electrical Insulation Materials

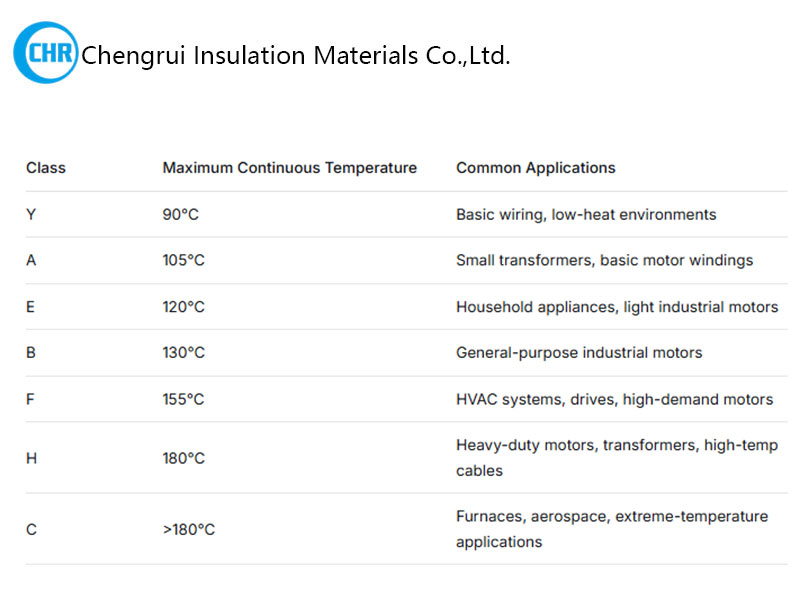

Heat resistance classes define how insulation materials perform under temperature—a key factor in electrical safety and system longevity. The heat resistance grades of electrical insulating materials commonly used in motors and transformers are divided into 7 grades: Y, A, E, B, F, H, and C.

What Are Heat Resistance Classes?

Heat resistance classes categorize insulation materials based on their maximum allowable continuous operating temperature—the temperature at which they can reliably function throughout their expected service life, typically defined as 20,000 hours of operation. These classifications, standardized under IEC 60085, help engineers select materials that prevent overheating, ensure durability, and minimize failure risks.

The 7 heat resistance grades:

Y(90℃) A(105℃) E(120℃) B(130℃) F(155℃) H(180℃) C(>180℃)

Class A (105℃) materials include diamond dotted paper, insulation pressphan paper & pressboard, insulation cable paper, crepe paper and tubes, ladder duct & transformer pressboard strips, densified laminated wood sheet, 2715 PVC fiberglass sleeving, 2310 oil synthetic varnish cloth tape etc.

Class E(120℃) materials include electrical fish paper with film, 6520 6521 insulation paper, 6020/6021 polyester(PET) film, 3025 phenolic cotton cloth laminated sheet, 3021 phenolic paper laminated sheet, etc.

Class B (130℃) materials include 6630-B DMD paper, 3240 epoxy glass cloth laminated sheet, FR4/G10/G11 epoxyglass cloth laminated sheet, etc.

Class F(155℃) materials include 6641-F DMD paper, 6640 NMN insulation nomex paper, AMA insulation paper, 2740 acrylic fiberglass sleeving, etc.

Class H(180℃) materials include 6650NHN paper, AHA paper, NMN insulation nomex paper-H, AMA insulation paper-H, 2753 silicone resin fiberglass sleeving, 2751 silicone rubber fiberglass sleeving, 6051 polyimide film, FH/FHF composite polyimide film etc.

Selecting the Right Heat Resistance Class

Consider these factors when choosing insulation:

Actual operating temperature – Add a 20-25°C safety margin above measured temperatures

Thermal cycling – Consider expansion/contraction effects in dynamic applications

Adjacent heat sources – Account for nearby components that may raise local temperatures

Certification requirements – Verify compliance with UL, IEC or industry-specific standards

Total cost of ownership – Higher heat resistance often means longer service life

Conclusion

Selecting the appropriate heat resistance class of electrical insulation materials is fundamental to ensuring system safety, reliability, and cost-effectiveness. By understanding the specific temperature requirements and operational environment of your application—and pairing them with the corresponding insulation class—you can significantly extend equipment lifespan and minimize downtime. Each class serves a distinct purpose across various industries and conditions.

Making an informed choice involves not just considering the maximum temperature, but also evaluating factors such as thermal cycling, mechanical stress, chemical exposure, and necessary certifications.

Need guidance in selecting the right insulation class for your specific project? Chengrui Insulation Materials Co.,Ltd. technical team is here to help you navigate the standards and identify the optimal material solution. Contact us for a professional consultation.

Quick Quote