Colorless Polyimide Film (CPI) Application

Discover the unique properties and applications of Colorless Polyimide Film (CPI). Explore its thermal stability and high transparency in flexible displays and aerospace.

In the high-stakes world of advanced materials, Polyimide (PI) has long been celebrated as the "Ultimate Engineering Plastic." While traditional polyimide films are famous for their signature amber or "golden" hue—providing unmatched heat resistance and insulation—they have one significant limitation: they are not transparent.

As we enter the era of foldable smartphones, flexible electronics, and next-gen aerospace optics, the industry has demanded a material that possesses the ruggedness of PI but with the clarity of glass. This demand has led to the rise of Colorless Polyimide Film (CPI), a high-performance polymer that is currently redefining the boundaries of display technology and beyond.

1. The Science: Why "Colorless" Matters

The transition from traditional yellow PI to Colorless Polyimide Film is not merely aesthetic; it is a feat of molecular engineering. In conventional polyimides, the intense color is caused by Charge Transfer Complex (CTC) interactions between the molecular chains, which absorb blue light.

To create CPI, scientists introduce specific chemical groups—such as fluorine-containing monomers or alicyclic structures—to inhibit these electronic interactions. The result is a film that maintains the "noble" thermal properties of polyimides while achieving over 89% optical transparency.

2. Unmatched Physical and Chemical Properties

What makes Colorless Polyimide Film a focus of global tech giants? It offers a unique combination of properties that no other transparent plastic can match:

Exceptional Optical Clarity: With a remarkably low Yellowness Index (YI), CPI allows for true-to-life color reproduction, making it essential for high-end display covers.

Superior Thermal Stability: CPI features a high glass transition temperature, allowing it to withstand rigorous manufacturing processes like reflow soldering and vacuum deposition without deforming.

Extreme Flexibility & Durability: Unlike rigid glass, CPI can be folded hundreds of thousands of times with a small bend radius without showing signs of fatigue or cracking.

Chemical & Radiation Resistance: It is inherently resistant to harsh chemicals, UV radiation, and atomic oxygen, which is critical for both industrial environments and outer space.

Low CTE (Coefficient of Thermal Expansion): Its dimensional stability ensures that electronic circuits printed on the film remain intact even under extreme temperature fluctuations.

3. High-Precision Manufacturing Process

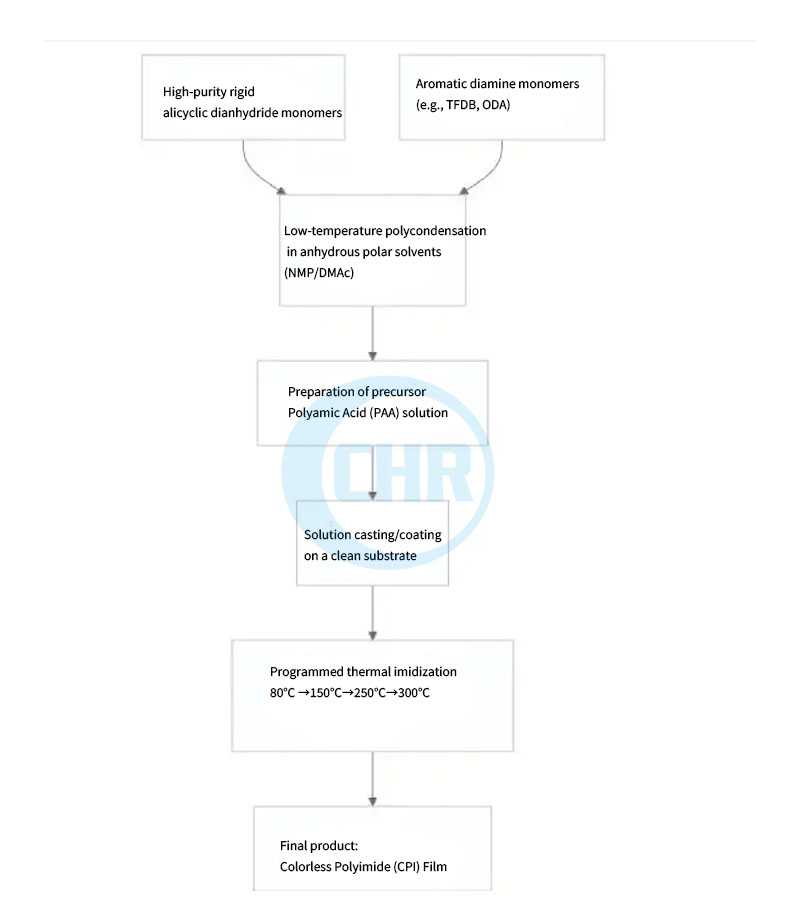

Producing premium Colorless Polyimide Film requires a stringently controlled environment and sophisticated synthesis:

High-Purity Monomer Selection: The process begins with ultra-pure monomers to prevent any "haze" or structural defects.

Solution Polymerization: Monomers are reacted to form Polyamic Acid (PAA). This solution is then cast onto a precision substrate using advanced flow-coating technology to ensure micron-level thickness uniformity.

Thermal Imidization & Biaxial Stretching: Through a multi-stage heating process, the film undergoes a chemical transformation into its final polyimide state. Biaxial stretching is often applied to optimize the mechanical strength and ensure optical isotropy across the entire surface.

4. Key Applications: Shaping the Modern World

The versatility of Colorless Polyimide Film has led to its adoption in several cutting-edge sectors:

◆ Foldable and Flexible Displays

CPI is the leading material for the "Cover Window" of foldable phones. It provides the necessary impact resistance and flexibility that ultra-thin glass (UTG) sometimes struggles to balance, offering a lighter and more shatter-proof solution.

◆ Aerospace and Defense

Due to its radiation resistance and thermal endurance, CPI is used in satellite thermal blankets, solar arrays, and cockpit windows. It protects sensitive instruments from the harsh environment of space while remaining optically clear.

◆ 5G/6G Communications and Printed Electronics

As a substrate for Flexible Printed Circuit Boards (FPC), CPI enables high-frequency signal transmission with minimal loss, thanks to its excellent dielectric properties.

◆ Next-Gen Optoelectronics

From flexible solar cells that can be wrapped around buildings to smart contact lenses and wearable biosensors, CPI is the invisible hero making "invisible tech" possible.

5. Future Outlook: The Path Forward

The global market for Colorless Polyimide Film is poised for explosive growth. Future research is focused on enhancing surface hardness (to match the scratch resistance of glass) and reducing production costs to enable mass-market adoption in automotive head-up displays (HUDs) and smart home interfaces.

As technology continues to move toward a more flexible, portable, and transparent future, CPI will undoubtedly remain at the center of innovation—a transparent bridge between today’s rigid devices and tomorrow’s seamless digital experiences.

Quick Quote