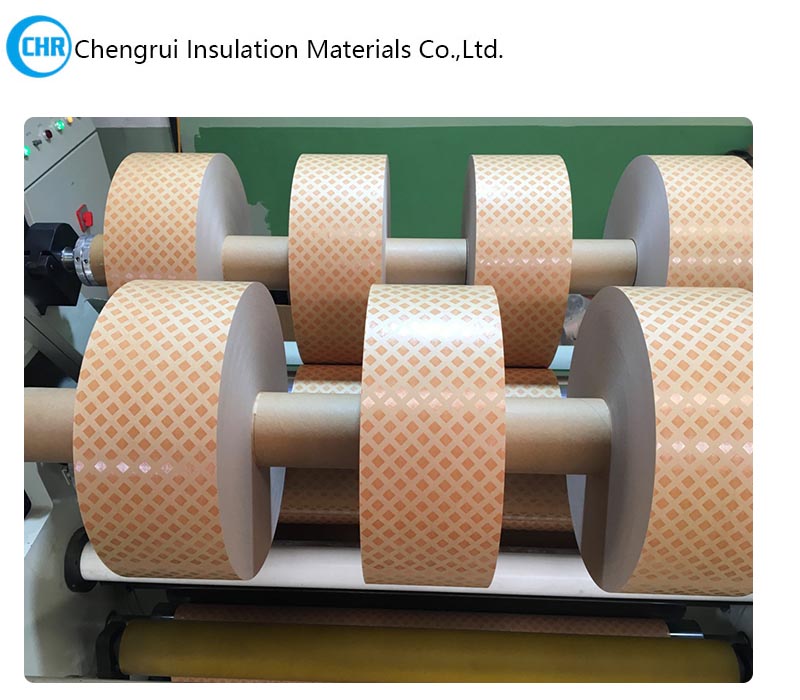

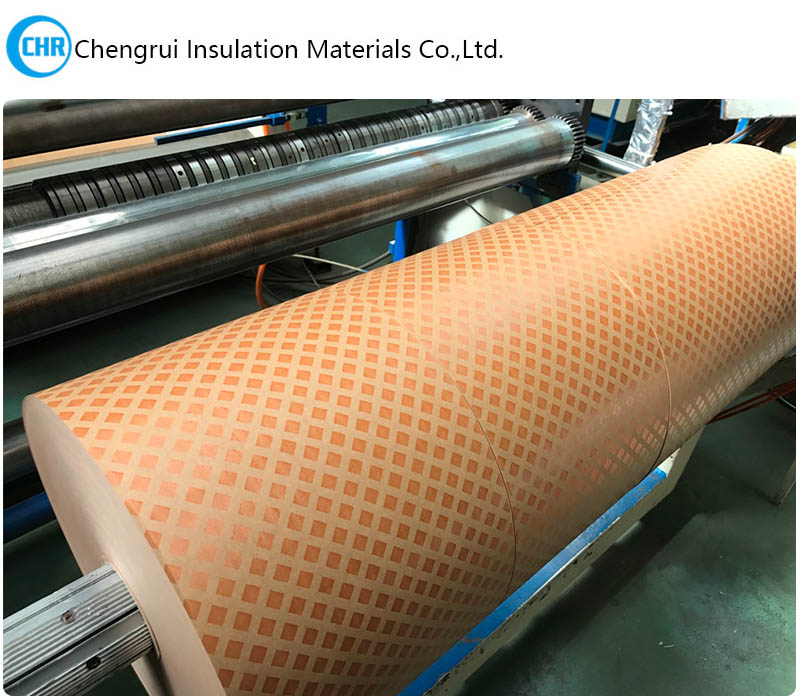

Ultimate Guide to Diamond Dotted Insulation Paper (DDP)

Introduction

In the world of high-voltage electrical equipment, the reliability of a transformer depends heavily on its insulation system. Among the various materials used, Diamond Dotted Paper (DDP) stands out as a critical component for oil-immersed transformers. But what exactly makes it indispensable? In this guide, we explore the structure, benefits, and technical specifications of DDP.

What is Diamond Dotted Paper (DDP)?

Diamond Dotted Paper is a specialized electrical insulation material made by applying a heat-curable epoxy resin in a diamond-shaped pattern onto high-quality electrical kraft paper.

The "diamond dots" are not just for show—they play a functional role in the structural integrity of the transformer coils.

How It Works: The Curing Process

When the transformer windings are heated during the drying process, the epoxy resin dots on the DDP melt and flow slightly. As the temperature rises further, the resin cures and hardens, creating a permanent bond between the paper and the conductor (wire).

Structural Bond: It creates a "bridge" that holds the winding layers together.

Oil Circulation: Because the resin is applied in dots rather than a solid layer, it leaves channels open for transformer oil to flow through, ensuring efficient cooling.

Key Benefits of Using DDP in Transformers

Short-Circuit Resistance: During a short circuit, mechanical stress can cause windings to shift. The bonding strength of cured DDP prevents this displacement, protecting the transformer from catastrophic failure.

Enhanced Heat Dissipation: The diamond pattern allows for maximum oil contact, reducing the risk of "hot spots" within the coils.

High Dielectric Strength: Made from 100% sulfate wood pulp, the base kraft paper provides excellent electrical insulation properties.

Technical Specifications & Standards

When sourcing DDP, engineers must look for specific technical parameters to ensure safety and longevity.

| Property | Typical Value | Test Method |

| Base Paper Thickness | 0.08mm - 0.50mm | IEC 60641 |

| Resin Content | 5% - 15% | Internal Standard |

| Temperature | Class A 105℃ | |

| Bonding Strength | ≥ 400 kPa | ASTM D-1002 |

How to Store and Handle DDP

Because DDP contains heat-curable resin, storage conditions are vital:

Temperature: Store in a cool environment (below 25°C).

Humidity: Keep in a dry place to prevent moisture absorption by the kraft paper.

Shelf Life: Typically 6–12 months depending on storage temperature.

Conclusion: Why Choose Chengrui DDP insulation paper?

At Chengrui Insulation, our Diamond Dotted Paper is manufactured to meet international IEC standards. We ensure precise resin distribution and consistent base paper quality to provide your transformers with the best mechanical and electrical protection.

Looking for a quote or a free sample? Contact our technical team today or visit our DDP Product Page.

Quick Quote