Mylar® Electrical Polyester Film in Insulation System

In electrical engineering, especially in the manufacture of motors and transformers, insulating materials are always indispensable. At the heart of many reliable insulation systems lies a material renowned for its exceptional balance of performance: Mylar® electrical polyester film. But what exactly makes it the cornerstone of modern electrical insulation?

It is its unique combination of mechanical strength, dielectric integrity, and heat resistance that makes it an indispensable choice for engineers.

Here are the key features of Mylar Electrical Polyester Film:

1. Superior Dielectric Strength

The primary function of any insulating material is to prevent current from flowing where it shouldn't. Mylar® polyester film excels in this regard.

○High Dielectric Strength: It can withstand high voltages on extremely thin sheets, making it an extremely efficient and space-saving insulating barrier. This allows for the design of more compact and powerful motors without compromising safety.

○Stable Performance: The film provides uniform insulation, free of pinholes or weak points, ensuring stable and reliable performance of equipment throughout its entire service life.

2. Superior Durability: Excellent Mechanical Properties

Inside motors, insulation materials face significant physical challenges, including vibration, friction, and stress during winding.

○Tensile Strength and Toughness: The biaxial orientation process during manufacturing imparts high tensile strength and puncture resistance to the film. It can withstand the harsh conditions of automated winding and lamination without tearing.

○Dimensional Stability: Minimal stretching or shrinkage at high temperatures. This stability is crucial for maintaining precise insulation positioning and preventing gaps or wrinkles that could lead to electrical failures.

3. High Temperature Resistance: Reliable Thermal Performance

The operating temperature of the motor directly determines the required insulation grade.

○Thermal Rating: Mylar® polyester film is typically rated for Class E (120°C) continuous operation. This makes it a versatile and cost-effective solution for a wide range of industrial motors and transformers.

○Thermal Stability: It maintains its critical mechanical and electrical properties over a wide temperature range, ensuring stable performance from start-up to full-load operation.

4. Use in Composite Materials

In the field of insulation, one of its most important roles is as a key component of composite materials.

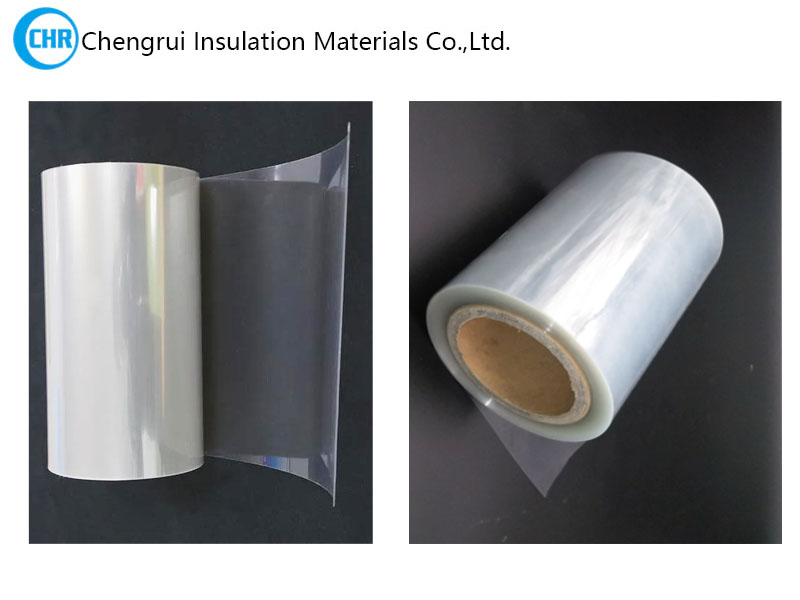

The "M" in DMD and NMN: Mylar® film is the core strength layer of these widely used composite insulation materials. Here the Mylar film is transparent color.

In DMD composite paper(nonwoven fabric- Mylar film-nonwoven fabric), it works with nonwoven fabric to form a robust sheet, ideal for gap insulation and interphase insulation.

In NMN composite paper(Nomex paper-Mylar film-Nomex paper), it acts as a dielectric barrier between Nomex paper layers, forming a high-performance, flexible insulation system suitable for harsh applications.

Application Areas: Mylar® polyester film has extensive and in-depth applications in electrical insulation, mainly categorized as follows:

1. Motor Insulation - Core Application Area

Slot Insulation: Serves as the inner lining of the stator or rotor core slots in motors, directly protecting the winding conductors from contact with the core, acting as the first line of defense against short circuits to ground.

Interlayer/Phase Insulation: Used to isolate coils or phases at different potential levels in motor windings, preventing turn-to-turn or phase-to-phase short circuits.

Pad Insulation: Used at winding ends and other locations as a supporting and insulating padding material.

Converter Insulation: Serves as wrapping tape or bushing, protecting leads and connection points.

2. Transformer Insulation

Used for interlayer and isolation insulation in dry-type transformers, its high dielectric strength and mechanical strength meet the compact design and safety requirements of transformers.

3. As a base material, it can be combined with other materials to form stronger insulating materials, such as DMD composite paper or NMM composite paper.

Mylar® electrical polyester film isn't just a generic plastic film. It is a precision-engineered material whose properties are perfectly aligned with the demands of the electrical insulation industry. Its synergy of electrical insulation, mechanical ruggedness, and thermal endurance makes it a special and often irreplaceable component in ensuring the longevity and reliability of motors and transformers worldwide.

Quick Quote