Bakelite Sheet Guide

Are you looking for Insulation Bakelite Sheets useful info? This post covers everything about Bakelite sheets to let you become expert on this insulation material. You can find useful tips and supplier lists to source Bakelite sheets for your business.

What is a Bakelite Sheet?

Invented in 1907 by Leo Baekeland, Bakelite is the world's first synthetic plastic. A Bakelite sheet is a phenolic laminate formed through a high-pressure reaction between phenol and formaldehyde with a filler material like wood pulp, canvas, or fiberglass. This creates a thermosetting polymer known for its exceptional thermal stability, electrical insulation, and chemical resistance.

Unlike thermoplastics, Bakelite doesn't melt once cured. With a dielectric strength exceeding 12 kV/mm and heat tolerance up to 300°F (149°C), it remains a critical material in high-voltage switchgear, circuit breakers, busbar isolators, and transformer spacers where failure is not an option.

A Brief History of Bakelite

While attempting to replicate shellac, Leo Baekeland accidentally created Bakelite in his Yonkers workshop. Its unique properties quickly made it a hallmark of the Roaring Twenties and Art Deco era, found in everything from Philips radios to jewelry. Its resilience made it indispensable in WWII military equipment. Though later overshadowed by newer plastics, its legacy endures in both collectibles and demanding industrial applications.

Key Functions and Advantages

Bakelite sheets serve three primary functions:

1. Electrical Insulation: Excellent dielectric strength makes it ideal for circuit breakers and fuse blocks.

2. Structural Support: Used as low-friction spacers, gears, and bearings in machinery.

3. Thermal Buffering: Withstands continuous temperatures up to 150°C, perfect for engine components and appliance handles.

Advantages of Bakelite Sheets:

☆Heat Resistance: Performs reliably up to 300°F (150°C).

☆Dimensional Stability: Does not warp or soften under high heat.

☆Mechanical Strength: High compressive and flexural strength.

☆Chemical Inertness: Resists acids, solvents, and corrosion.

☆Economical: Long service life reduces replacement frequency.

☆Arc Resistance: Inherently resists electrical tracking.

Is Bakelite Sheet Waterproof?

Yes. Bakelite is virtually impervious to moisture, with water absorption rates as low as 0.03%. This property made it a superior replacement for wood in early electrical systems exposed to humid environments. It is commonly used in marine applications, plumbing seals, and other settings where moisture resistance is critical.

Bakelite Sheet Applications

Beyond classic radios and telephones, Bakelite sheets are found in:

Automotive: Distributor rotors, brake pads, ignition components.

Industrial: Conveyor skid plates, press brake blocks, insulator spacers.

Electronics: High-voltage transformer insulation, fuse blocks, commutator V-rings.

Consumer Goods: Appliance handles, kitchenware, and even durable guitar picks.

Specialized Uses: Radiation shielding, lab equipment, and forensic work surfaces.

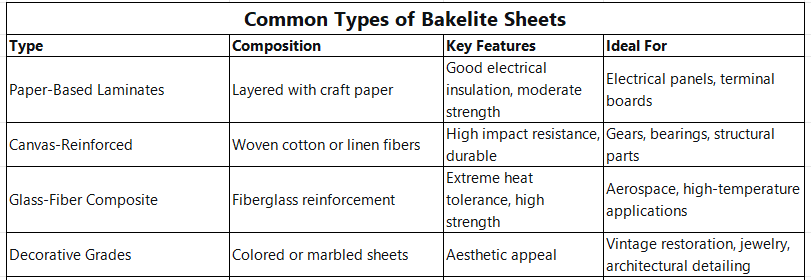

How to Choose the Right Bakelite Sheet

Selecting the correct grade is crucial for performance and longevity. Consider these factors:

1. Application: Determine the primary need (electrical insulation, mechanical strength, heat resistance).

2. Reinforcement: Choose paper for electrical, canvas for impact, and fiberglass for extreme heat.

3. Thickness: Ranges from 1.6mm (1/16") for electronics to 50mm (2") for heavy industrial use. Standard sizes are 4x8 ft (1220x2440mm).

4. Certifications: Ensure compliance with relevant standards like UL 94 V-0 (flame retardant), ASTM D709, or IEC 60893.

5. Supplier Reliability: Source from reputable manufacturers who provide test reports and samples.

Pro Tip: Always request a sample to test for machinability, heat resistance, and overall quality before placing a bulk order.

Sourcing and Importing: A Practical Guide

Where to Buy Bakelite Sheets:

You can find suppliers through industrial plastic distributors, online marketplaces like Alibaba, or direct from manufacturers. For bulk industrial use, partnering directly with a factory is often most cost-effective.

Is Chinese Bakelite Sheet Reliable?

China is a major producer of both high and low-quality Bakelite. Yes, it can be reliable if you perform due diligence.

Vet Suppliers: Look for manufacturers with ISO 9001 certification and positive export history.

Request Reports: Ask for third-party lab test reports from SGS or Intertek for mechanical and electrical properties.

Get Samples: Test samples rigorously before committing to a large order.

Focus on Hubs: Industrial clusters in provinces like Henan (e.g., Xuchang City) offer a strong balance of quality and cost due to local raw material access.

The Importing Process:

Supplier Agreement: Negotiate terms (MOQ, Price, Incoterms like FOB).

Compliance: Ensure materials meet your country's regulations (e.g., REACH, RoHS).

Shipping: Choose air freight for speed or sea freight for cost-effectiveness on large orders.

Customs Clearance: Provide correct documentation (SDS, Invoice, HS code 3917.29).

Quality Inspection: Inspect goods upon arrival for damage or specification deviations.

Frequently Asked Questions (FAQ)

Q1: What is the price of Bakelite per kg?

Prices range from $5–$30 per kg. Standard industrial grades cost $5–$15/kg, while specialized or reinforced grades can reach $20–$30/kg. Bulk orders typically receive significant discounts.

Q2: What is the service life of a Bakelite sheet?

In controlled environments, Bakelite sheets can last 30 to 50 years or more. Service life depends on application conditions like continuous temperature, thermal cycling, and exposure to chemicals or UV light.

Q3: Is Bakelite toxic?

Fully cured Bakelite sheets are generally considered safe and non-toxic for handling and use. However, machining it generates dust that requires respiratory protection. Always ensure modern sheets are compliant with RoHS and REACH standards, which restrict hazardous substances.

Q4: Is Bakelite fireproof?

Bakelite is not fireproof but is fire-resistant. It holds a UL 94 V-0 rating, meaning it is self-extinguishing—it will stop burning once the flame source is removed. Under direct and extreme heat, it will char and decompose rather than melt.

Q5: Can I get a sample before ordering?

Yes, and you always should. Reputable suppliers will provide samples, sometimes for free if you cover shipping. Use the sample to verify thickness, color, machinability, and performance under expected conditions.

Conclusion

Bakelite sheet is a time-tested engineering material that continues to offer unparalleled value in applications demanding robust electrical insulation, thermal stability, and mechanical strength. By understanding its properties, advantages, and the intricacies of the global supply chain, you can confidently source high-quality Bakelite sheets that ensure reliability and cost-effectiveness for your projects.

Ready to Source Bakelite Sheets? Use this guide to identify your needs, vet potential suppliers, and secure the best material for your business.

Quick Quote