Nomex Insulation Paper for Motor Winding

Motor winding insulation grades (e.g., Class A, B, F, H) indicate thermal tolerance. Higher grades like Class H (180°C) suit demanding applications like industrial motors, while Class F (155°C) balances cost and durability for commercial use. Always match insulation grade to operating temperatures to prevent overheating and extend motor life.

What Class of Insulation Is Best for Motors

The "best" insulation class depends on operational needs. Class F is widely preferred for its balance of heat resistance (155°C) and affordability. For extreme conditions, Class H offers superior thermal stability. Prioritize energy efficiency and lifespan when selecting insulation to avoid premature motor failure.

Types of Insulation Paper for Motor Winding

Insulation papers for windings include Nomex (aramid), Mylar (polyester), and fish paper (vulcanized fiber). Nomex excels in high-temperature environments, while Mylar provides moisture resistance. Fish paper is economical for low-voltage applications.

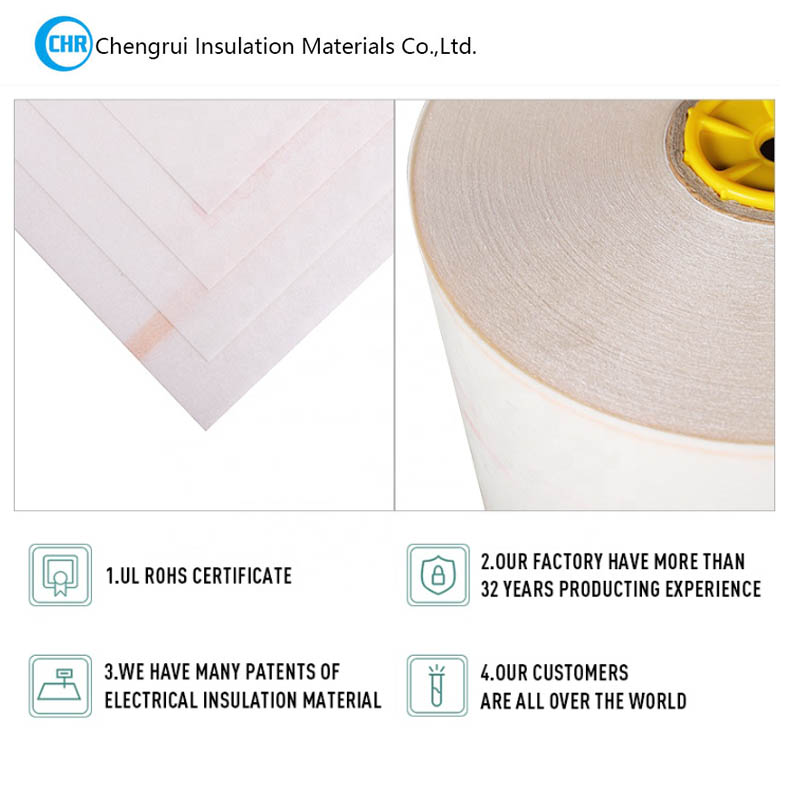

Chengrui can offer nomex insulation paper for motor winding as follows:

1. DuPont® Nomex® 410 paper. This is the foundational material that provides inherent heat resistance, mechanical toughness, and dielectric strength.

2. NMN Composite Paper: By sandwiching a layer of polyester film (PET) between two layers of Nomex paper, this type significantly enhances dielectric strength and puncture resistance while maintaining excellent heat resistance. It is one of the standard choices for high-performance Class H (180°C) motors.

3. NHN Composite Paper: This variant replaces the central PET film with a polyimide film, granting it superior high-temperature resistance. It can be reliably used in high temp and above applications, or in scenarios demanding extreme long-term thermal stability.

Specifications of Nomex Insulation Paper for Motor Winding

Nomex 410/414 is a go-to insulation paper for motors. Key specs include thickness (0.05–0.25mm), dielectric strength (>40 kV/mm), and thermal stability up to 220°C. Its flame-retardant properties make it ideal for aerospace and EV motors.

Property | Value |

Thickness Range | 0.05–0.25 mm |

Thermal Class | 220°C (Class H) |

Dielectric Strength | >40 kV/mm |

Flame Resistance | Self-extinguishing (UL 94 V-0) |

Common Applications | EVs, aerospace, heavy machinery |

Why nomex insulation paper is suitable for motor winding

Nomex insulation paper is ideal for motor windings due to its unmatched heat resistance (up to 220°C) and flame-retardant properties. Unlike traditional materials, it maintains structural integrity under high thermal stress, preventing short circuits. Its lightweight, flexible design adapts to tight winding spaces without tearing. Nomex also resists chemicals, moisture, and abrasion, ensuring longevity in harsh environments like EVs or industrial machinery. By minimizing electrical losses and enhancing safety, it’s a top choice for high-performance motors.

Feature | Benefit |

High thermal class | Withstands extreme heat without degrading |

Flame resistance | Meets UL 94 V-0 safety standards |

Chemical resistance | Durability in corrosive settings |

Lightweight | Easy handling and installation |

Motor Winding Nomex Insulation Paper Price

Nomex paper costs vary by thickness, grade, and supplier. Standard grades like Nomex 410 range from $20–50 per square meter, while specialized types (e.g., Nomex 418) can exceed $80. Bulk orders often reduce costs by 10–20%,

Regional factors matter—Asian suppliers may offer lower rates than North American or European distributors. Always compare certifications and minimum order quantities to balance budget and quality.

Factor | Price Impact |

Thickness (0.05–0.25mm) | Thicker = higher cost |

Quantity | Bulk discounts available |

Supplier region | Asia vs. Western pricing differences |

Certifications | UL-listed grades cost more |

What Is the Specific Type of Nomex Insulation Paper for Motor Winding

Motor windings commonly use Nomex 410, 414, or 418. Nomex 410 (0.05–0.15mm) suits low-voltage applications. Nomex 414 (0.15–0.25mm) offers higher dielectric strength for EVs. Nomex 418, with added aramid layers, handles extreme thermal stress in aerospace motors. Each type is UL-certified, but match thickness and class to your motor’s voltage and temperature needs.

Type | Thickness | Application |

Nomex 410 | 0.05–0.15mm | Small appliances, low-voltage |

Nomex 414 | 0.15–0.25mm | EVs, industrial motors |

Nomex 418 | 0.25mm+ | Aerospace, heavy machinery |

How Do You Measure Motor Winding Nomex Insulation Paper Quality

Test Nomex quality using thermal stability checks (exposure to 220°C for 48 hours), dielectric strength tests (>40 kV/mm), and thickness consistency (micrometer measurements). Verify flame resistance via UL 94 V-0 certification. Inspect for uniformity—no pinholes or wrinkles—and chemical resistance by exposing samples to oils or solvents. Reputable suppliers provide test reports.

Test | Standard |

Thermal aging | 220°C for 48 hours, no degradation |

Dielectric strength | >40 kV/mm |

Flame resistance | UL 94 V-0 compliance |

Thickness tolerance | ±0.02mm |

How to Choose Nomex Insulation Paper for Motor Winding

Select Nomex based on operating temperature, voltage, and environment. For high-heat motors (e.g., industrial), opt for Class H (220°C) grades like Nomex 414. Prioritize dielectric strength (>35 kV/mm) for high-voltage applications. Ensure flexibility if windings have complex shapes. Check supplier certifications (UL, ISO) and request samples to test compatibility with your manufacturing process.

Criteria | Guideline |

Temperature class | Match to motor’s max operating heat |

Dielectric strength | Higher kV/mm for high-voltage systems |

Flexibility | Crucial for intricate winding designs |

Supplier proof | Demand UL/ISO certifications |

Where to Source Nomex Insulation Paper for Motor Winding

Source Nomex directly from DuPont-authorized distributors (e.g., Direct Textile Store) or industrial suppliers like RS Components. Online platforms (AliBaba, Thomasnet) list global vendors—verify reviews and certifications. For cost efficiency, consider Asian suppliers like Mitsubishi Chemical, but confirm quality via lab tests. Local electrical material wholesalers often stock Nomex for faster delivery.

Source | Pros | Cons |

DuPont distributors | Guaranteed quality, certifications | Higher cost |

Online marketplaces | Competitive pricing, global options | Risk of counterfeit products |

Local wholesalers | Fast shipping, easy returns | Limited stock variety |

Can I Import Motor Winding Nomex Insulation Paper from China

Yes, importing Nomex insulation paper from China is common and cost-effective. Many Chinese suppliers offer competitive pricing due to lower production costs. However, verify certifications like UL or ISO to ensure quality compliance. Shipping and customs duties can add costs, so request detailed quotes upfront. Work with suppliers who provide samples for testing and have transparent documentation. Be cautious of delays—plan orders well in advance. Partnering with a reputable sourcing agent can streamline the process.

Aspect | Consideration | Example |

Supplier Verification | Check UL/ISO certifications | Request test reports |

Shipping Costs | Include tariffs and logistics | Compare FOB vs. CIF pricing |

Lead Time | Factor in production and transit | Plan 6–8 weeks ahead |

Quality Assurance | Test samples before bulk orders | Confirm dielectric strength |

Quick Quote