How to Choose Transformer Insulation Materials

Selecting appropriate transformer insulation materials is a fundamental part of transformer design and manufacturing. Insulation performance directly affects dielectric strength, thermal endurance, mechanical stability, and long-term service life. In practical transformer production, insulation materials should be selected according to their function within the insulation system rather than treated as interchangeable components.

Based on common industry practice, the following materials form the core insulation system used in most power and distribution transformers.

1. Kraft Insulation Paper – The Foundation of Winding Insulation

Kraft insulation paper, also known as cable paper, is one of the most widely used insulation materials for transformers. It is primarily applied for conductor wrapping and interlayer insulation in transformer windings.

Its stable dielectric strength, oil compatibility, and uniform thickness make it a reliable base material in oil-immersed transformer designs. In most transformer insulation systems, kraft paper serves as the fundamental electrical barrier between conductors and layers.

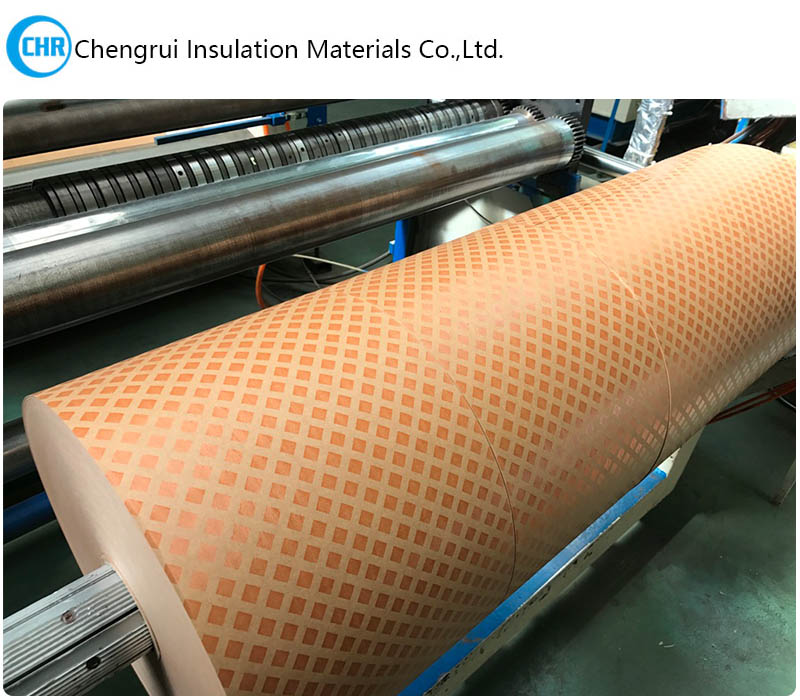

2. Diamond Dotted Paper for Layer Bonding and Mechanical Stability

Diamond dotted paper (DDP) is commonly used as interlayer insulation in transformer windings. The thermosetting resin dots allow layers to bond during curing, which improves mechanical stability and reduces conductor movement under short-circuit conditions.

In modern transformer manufacturing, diamond dotted paper plays an important role in enhancing winding integrity while maintaining good dielectric performance. It is widely applied in both power and distribution transformers.

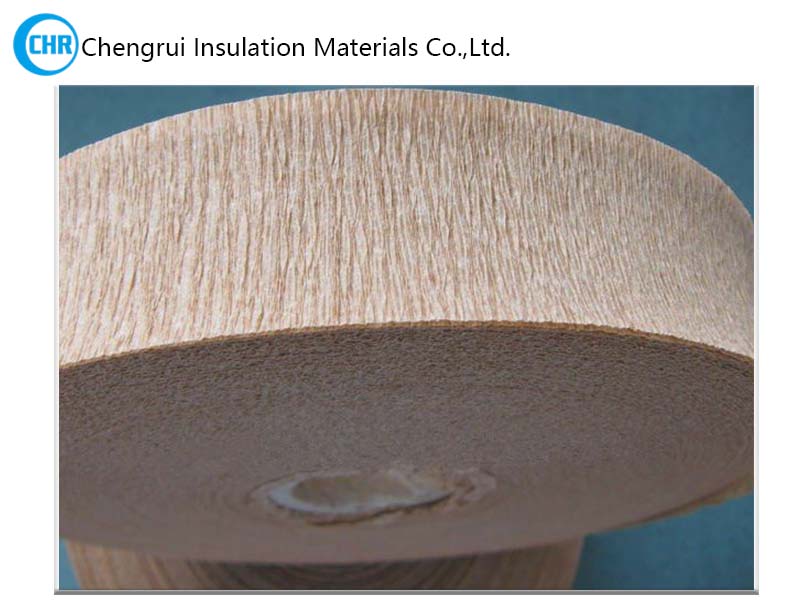

3. Crepe Paper for Flexible and Lead Insulation Applications

Crepe paper insulation is mainly used in areas requiring flexibility, such as lead insulation, corner insulation, and curved sections of transformer windings. Its stretchability allows it to adapt to complex geometries without tearing.

Crepe paper and crepe paper tubes are also commonly applied in oil-immersed transformers where good oil impregnation and mechanical adaptability are required.

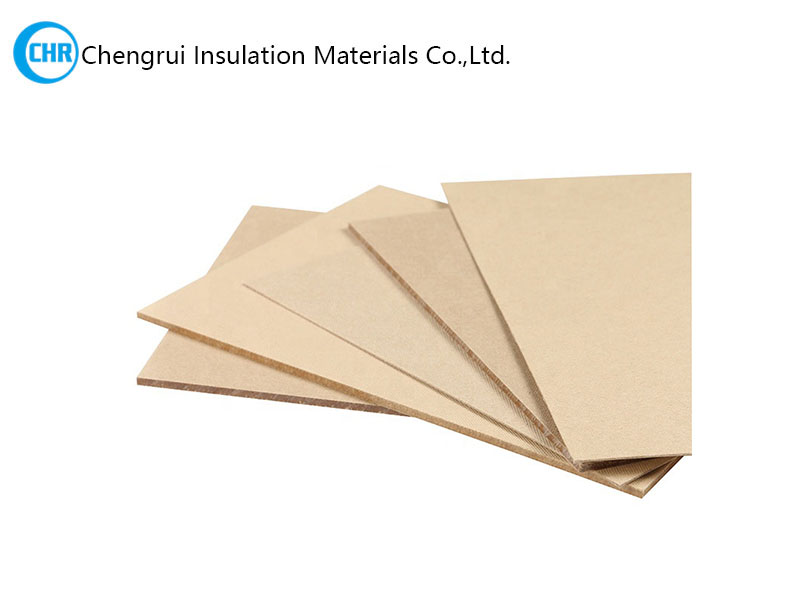

4. Insulation Pressboard for Structural Components

Insulation pressboard is used for structural insulation components such as spacers, barriers, end rings, and support elements. Unlike paper-based winding insulation, pressboard provides higher mechanical strength and dimensional stability.

Proper selection of pressboard is essential to maintain electrical clearances and ensure long-term structural reliability inside the transformer.

5. Thermally Upgraded Paper for Higher Temperature Performance

Thermally upgraded paper (TUP) is increasingly used in transformer designs requiring improved thermal endurance. Compared with standard kraft paper, TUP offers better resistance to thermal aging, helping extend transformer service life under higher operating temperatures.

This material is commonly selected for transformers designed with higher thermal class requirements or extended lifetime expectations.

Practical Considerations When Selecting Transformer Insulation Materials

When choosing insulation materials for transformers, manufacturers should consider operating voltage, thermal class, mechanical stress, oil compatibility, and long-term aging performance. A reliable transformer insulation materials supplier should provide consistent material quality, controlled tolerances, and stable supply for bulk production.

For a complete overview of insulation solutions, visit our Transformer Insulation Materials page.

FAQs About Transformer Insulation Materials

Q:What insulation materials are commonly used in transformers?

A:Kraft paper, diamond dotted paper, crepe paper, insulation pressboard, and thermally upgraded paper form the core insulation system in most transformer designs.

Q:Why is diamond dotted paper used in transformer windings?

A:It provides interlayer insulation while improving mechanical bonding and winding stability during operation.

Quick Quote